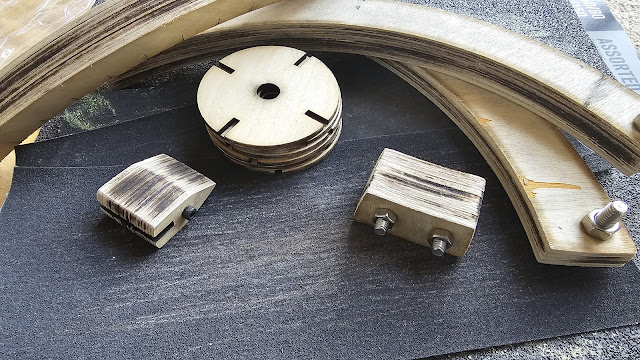

The plywood pieces had soot along the cut edges, which would gunk up the adhesive LED strips and probably interfere with the paint. I bolted the pieces together and removed the ash with coarse sandpaper.

I drilled and cut a circle of hardware store plywood. There were three hole sizes for the wooden slats, clock movement, and quadrant dividers. Cutting the circle with a jigsaw on a dark patio was the hardest part. I sanded the edges to prevent slivers.

I put white contact paper on the clock face and blackened the bezel pieces with a permanent marker. Paint would have been less expensive, but it would have taken longer, and I did all these things in my living room.

I assembled the clock walls, added an inward-facing LED strip around the rim, and the black bezel pieces. I used a razor knife to carve out a groove at the top where I could pass the LED strip wires. I need something to cover the conductors and a microcontroller.

I designed and cut a couple of wood pieces for the top of the clock, where I can mount buttons and a microcontroller. These pieces were much too large, but I needed to be sure I could fit everything. If it is a problem, I can cut new ones.

I mounted the microcontroller demo board by drilling four holes and bolting it to the mounting plane. I removed the LED strip's pluggable header, soldered the wires to my controller, and added the lid.

The rest of the summary posts have been arranged by date.

First time here?

Completed projects from year 1

Completed projects from year 2

Completed projects from year 3

Completed projects from year 4

Completed projects from year 5

Completed projects from year 6

Completed projects from year 7

Completed projects from year 8

Completed projects from year 9

Completed projects from year 10

Completed projects from year 11

Disclaimer for http://24hourengineer.blogspot.com and 24HourEngineer.com

This disclaimer must be intact and whole. This disclaimer must be included if a project is distributed.

All information on this blog, or linked by this blog, is not to be taken as advice or solicitation. Anyone attempting to replicate, in whole or in part, is responsible for the outcome and procedure. Any loss of functionality, money, property, or similar, is the responsibility of those involved in the replication.

All digital communication regarding the email address 24hourengineer@gmail.com becomes the intellectual property of Brian McEvoy. Any information contained within these messages may be distributed or retained at the discretion of Brian McEvoy. Any email sent to this address, or any email account owned by Brian McEvoy, cannot be used to claim property or assets.

Comments to the blog may be utilized or erased at the discretion of the owner. No one posting may claim property or assets based on their post.

This blog, including pictures and text, is copyright to Brian McEvoy.

|

| Clean edges |

I drilled and cut a circle of hardware store plywood. There were three hole sizes for the wooden slats, clock movement, and quadrant dividers. Cutting the circle with a jigsaw on a dark patio was the hardest part. I sanded the edges to prevent slivers.

|

| Circular panel with holes |

I put white contact paper on the clock face and blackened the bezel pieces with a permanent marker. Paint would have been less expensive, but it would have taken longer, and I did all these things in my living room.

|

| White face and black bezel pieces |

I assembled the clock walls, added an inward-facing LED strip around the rim, and the black bezel pieces. I used a razor knife to carve out a groove at the top where I could pass the LED strip wires. I need something to cover the conductors and a microcontroller.

|

| Assembled, except for the microcontroller |

I designed and cut a couple of wood pieces for the top of the clock, where I can mount buttons and a microcontroller. These pieces were much too large, but I needed to be sure I could fit everything. If it is a problem, I can cut new ones.

|

| Bottom bolted and top blackened |

I mounted the microcontroller demo board by drilling four holes and bolting it to the mounting plane. I removed the LED strip's pluggable header, soldered the wires to my controller, and added the lid.

|

| ESP32 demo board between the layers |

The rest of the summary posts have been arranged by date.

First time here?

Completed projects from year 1

Completed projects from year 2

Completed projects from year 3

Completed projects from year 4

Completed projects from year 5

Completed projects from year 6

Completed projects from year 7

Completed projects from year 8

Completed projects from year 9

Completed projects from year 10

Completed projects from year 11

Disclaimer for http://24hourengineer.blogspot.com and 24HourEngineer.com

This disclaimer must be intact and whole. This disclaimer must be included if a project is distributed.

All information on this blog, or linked by this blog, is not to be taken as advice or solicitation. Anyone attempting to replicate, in whole or in part, is responsible for the outcome and procedure. Any loss of functionality, money, property, or similar, is the responsibility of those involved in the replication.

All digital communication regarding the email address 24hourengineer@gmail.com becomes the intellectual property of Brian McEvoy. Any information contained within these messages may be distributed or retained at the discretion of Brian McEvoy. Any email sent to this address, or any email account owned by Brian McEvoy, cannot be used to claim property or assets.

Comments to the blog may be utilized or erased at the discretion of the owner. No one posting may claim property or assets based on their post.

This blog, including pictures and text, is copyright to Brian McEvoy.

Comments

Post a Comment